One year after the implementation of Supreme Decree No. 8 (DS 8), which enforces the Extended Producer Responsibility (EPR) Law for priority tyre products, tyre retreading has emerged as a crucial sustainable, safe, and efficient solution to meet the Ministry of the Environment’s goals.

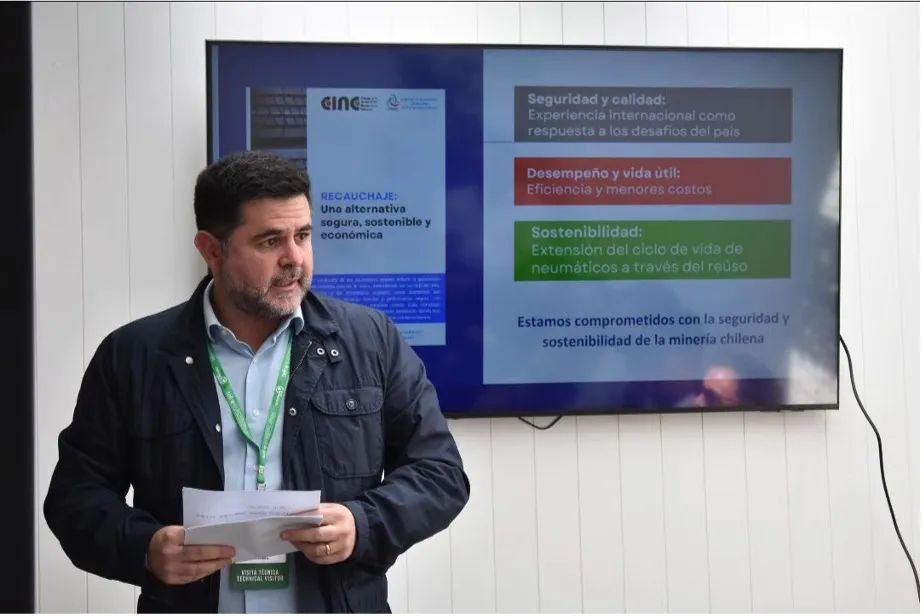

A recent discussion panel titled “Retreading and Circularity: A Safe, Efficient, and Sustainable Solution to Advance in the EPR Law” centred around analysing the results of DS 8 after its first year. The panel emphasised solutions focused on eco-design and strategies to prevent waste generation. This event was organised by the Chilean Chamber of the Tyre Industry (CINC), which includes members such as Bridgestone, Goodyear, Michelin, and Pirelli, in collaboration with the Chilean Association of Tyre Retreaders and Renovators (ARNEC).

Participants reviewed the retreading industry’s technological advancements, highlighting its role in sustainable tyre waste management. These advancements position retreading as a key strategy in meeting the EPR Law’s environmental targets.

The discussion underscored the significance of tyre retreading as an integral part of a circular economy, where products are designed and managed to maximise their lifecycle and minimise waste. By extending the life of tyres through retreading, the industry not only reduces the environmental impact but also offers a cost-effective and reliable alternative to new tyres.

The collaboration between major tyre manufacturers and retreading specialists symbolises a unified approach to tackling environmental challenges within the industry. It showcases a commitment to innovation and sustainability, aiming to meet regulatory requirements while promoting eco-friendly practices.

As Chile advances its environmental policies, the tyre retreading sector is expected to play a pivotal role. The ongoing efforts to integrate retreading into the broader framework of the EPR Law highlight its importance as a practical and effective solution for sustainable development.