At this year’s TyreXpo Asia, Hankook Tyres’ Guy Heywood highlighted the rapid transformation taking place in the mobility sector. While Heywood is a familiar face at industry events in Europe, this marked his first major presentation in Asia—an opportunity he embraced to engage with the region’s evolving tyre market and share insights from his three decades in the industry.

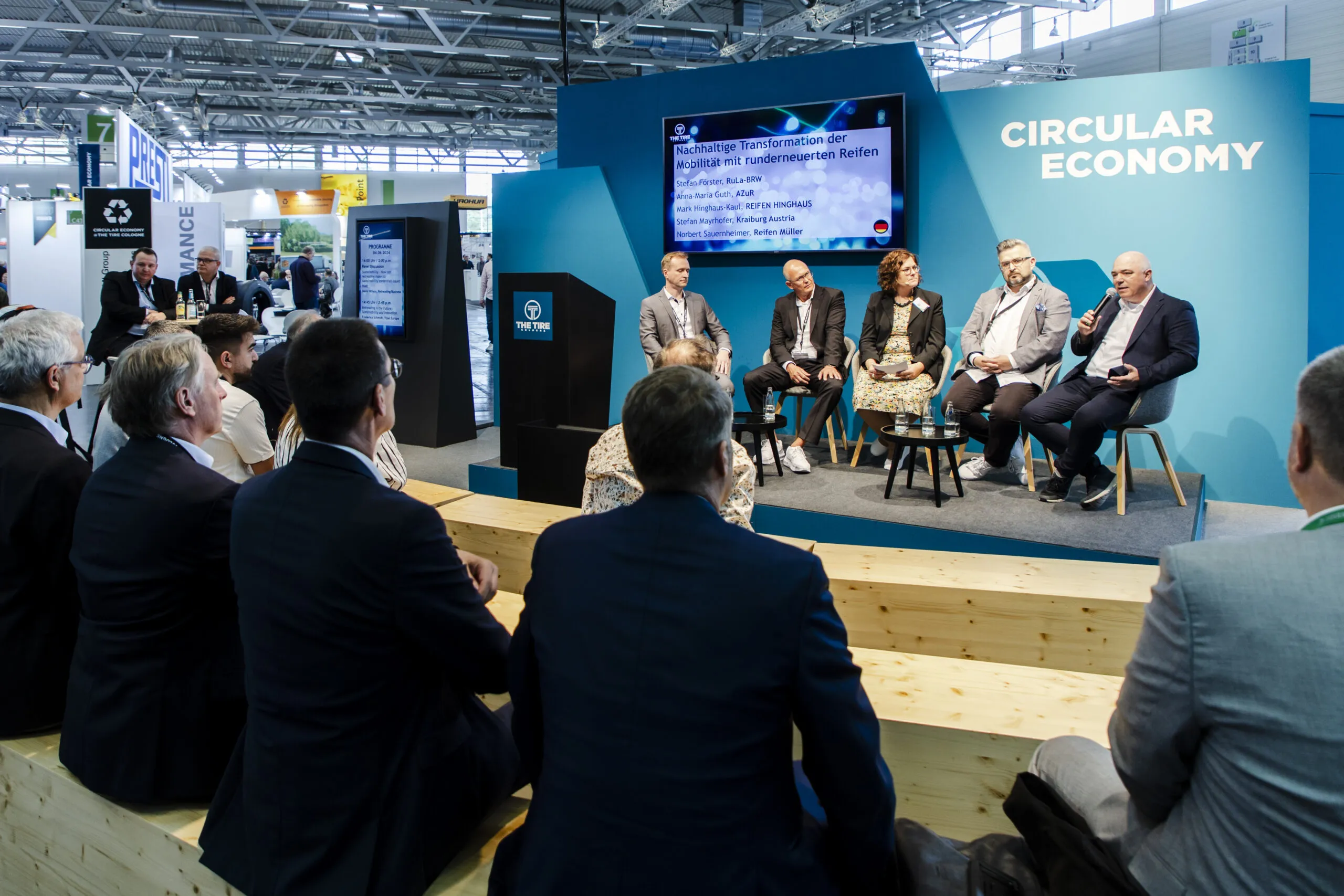

The Era of Dynamic Innovation

According to Heywood, the tyre sector is experiencing an unprecedented period of innovation. While changes in vehicle and tyre technology have historically been gradual, today’s advancements are accelerating at an extraordinary pace. Developments that would have taken decades in the past are now happening within just a few years, making this one of the most dynamic periods the industry has seen. New technologies such as artificial intelligence, 3D printing, and advanced material sciences are driving tyre performance improvements of up to 20% in multiple areas—surpassing even the impact of radial tyres 80 years ago.

For companies like Hankook, which aim to remain at the forefront of mobility solutions over the next decade, this technological revolution presents exciting opportunities. With Asia playing a key role in this transformation, TyreXpo Asia provided an ideal platform to explore industry trends, observe competitor developments, and discuss strategies for the future.

The Role of Retreading in a Changing Market

While the exhibition showcased a broad spectrum of tyre innovations, Heywood noted that retreading was somewhat underrepresented—something he found surprising given its relevance in the current market. Having previously managed a retreading factory in the UK, he remains a strong advocate for the practice, particularly in the context of sustainability and cost efficiency.

With the transition to electric and non-diesel commercial vehicles progressing slowly—EVs and alternative-fuel trucks accounted for just 5% of new commercial vehicle registrations in Europe last year—internal combustion engine (ICE) vehicles are set to remain on the roads for decades. This makes optimising tyre usage crucial for reducing both costs and environmental impact.

Heywood emphasised that the most fuel-efficient stage of a tyre’s life is when it is fully worn—a fact that many fleet operators overlook. By implementing regrooving, fleets can extend a tyre’s optimal fuel efficiency phase, improving mileage and reducing costs. Retreading further enhances this efficiency by giving tyres a second, or even third, life. The combination of regrooving and multiple retreading cycles allows fleets to maximise tyre value while significantly reducing waste and emissions.

Hankook’s Commitment to Retreading

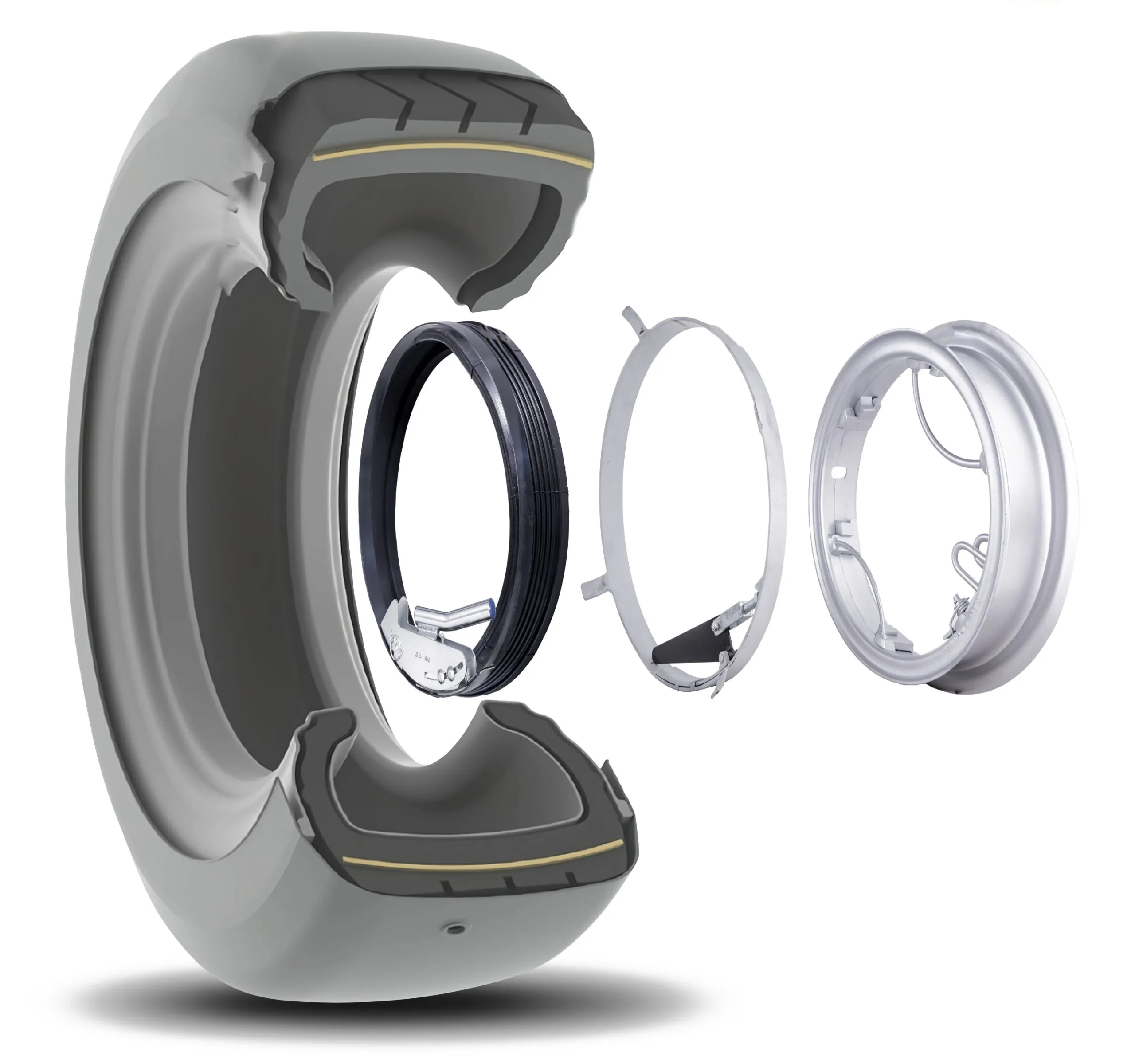

Recognising the benefits of retreading, Hankook has made significant investments in the sector. The company operates five retreading facilities in Europe and has plans to expand production in the coming years. Its approach is straightforward: start with a new Hankook tyre, regroove it, retread it, regroove the retread, and potentially retread it again—ensuring maximum value extraction at every stage.

Heywood illustrated the importance of this process with a simple analogy: if someone purchased a €70 bottle of wine, they wouldn’t leave 40% of it in the bottle—they would make sure to enjoy every last drop. Yet, many fleet operators effectively waste 40% of their tyres’ value by failing to regroove, retread, or maintain proper pressures. Many remove tyres at 6mm tread depth instead of 2mm, discarding a significant portion of their usable life.

Hankook’s message is clear: fleets should take full advantage of regrooving and retreading to lower operating costs and reduce environmental impact. Heywood believes that if a fleet is not willing to maximise the life of its tyres through these practices, it shouldn’t be investing in premium tyres at all.

As the tyre industry continues to evolve, the principles of efficiency and sustainability remain at the core of Hankook’s strategy. By encouraging fleets to ‘get all the wine out of the bottle,’ the company aims to promote smarter tyre management and ensure a more sustainable future for the industry.