Reifen Müller, who operate one of the most modern retread shops in Europe located in the centre of Germany, were looking for options to further automate their retread process as they were experiencing difficulties in finding skilled personnel to operate their machines. They explored a number of different options, but found that the VMI RETRAX with builder provided the best answer to their quest. The builder features an automatic alignment of the tread on the casing as well as an automatic stretching of the tread to match the circumference of the casing. Tread application is now done fully automatic at Reifen Müller, resulting in a higher accuracy with every retreaded tyre and a reduced labour involvement.

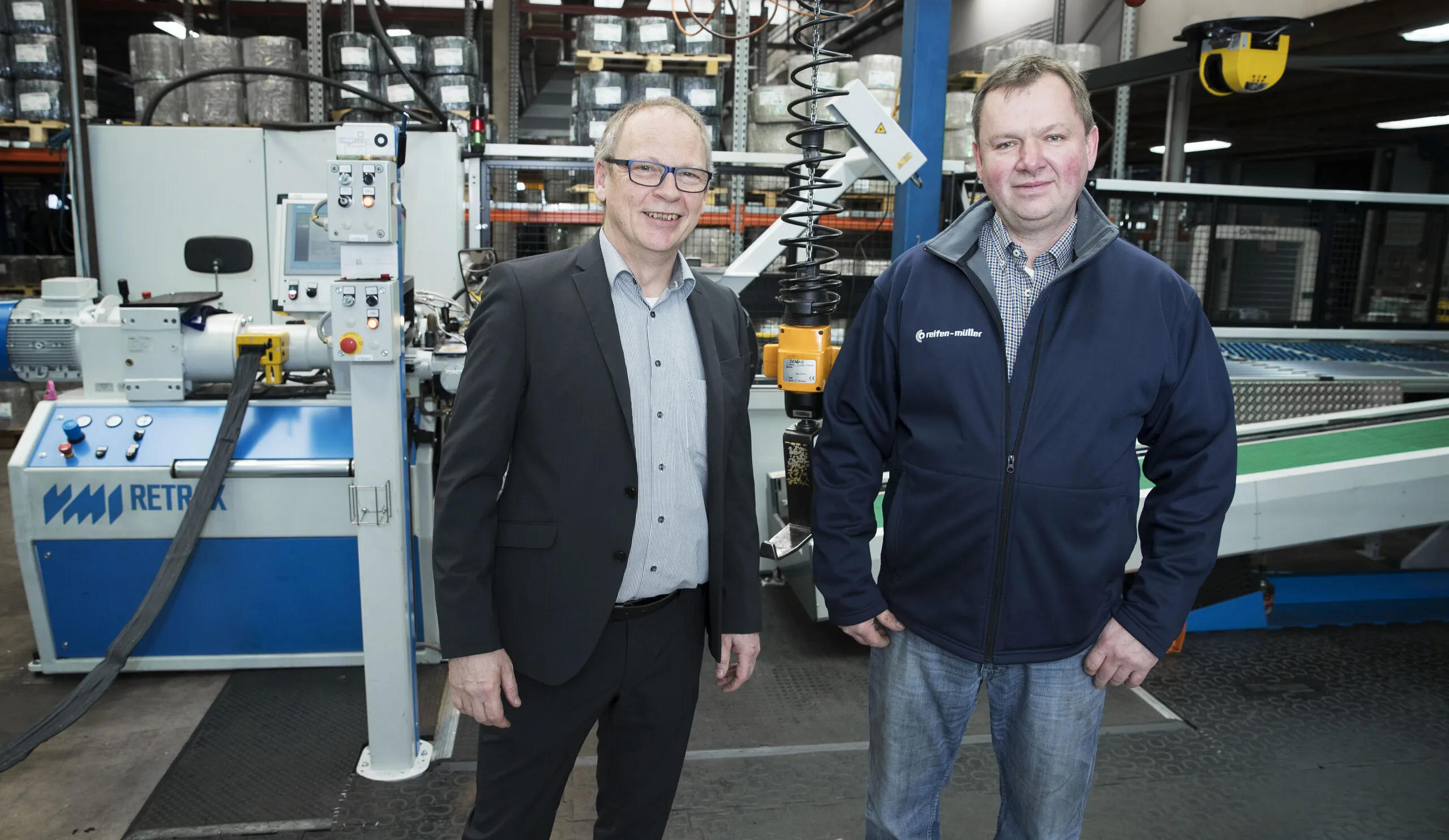

Reifen Müller Has Invested in Further Automation by Partnering with VMI

The VMI RETRAX retreading system combines the proven cushion gum smearing technology of the well-known AZ machine with the tyre building know-how from VMI. The result is a highly automated machine. As the machine itself measures and controls most of the process parameters, it is far easier to operate and to teach new operators how to make high quality tyres. Next to this, the balanced stretching of the builder provides a perfectly matching splice, and the tread tension is optimally distributed around the tire.

Compared to their previous retreading process, with the new solution, Reifen-Müller has been able to attain a production output increase of 10%. This further automation of the retreading process lowers the labour and material costs per retreaded tyre. As the operator does not have to fill the skives of a buffed tyre before the cushion gum is applied on the casing, considerable time savings are able to be achieved. Moreover, strip cushion gum is less expensive to produce than calendered sheet cushion gum.

Uwe Mueller, owner of Reifen-Müller commented; “The RETRAX with builder offers our operators very easy maintenance and a user-friendly operation. The fact that we can teach a new operator to operate the machine within 2 days is a huge benefit for us. In addition, the high automation level results in less variation in the retreaded tyres.”