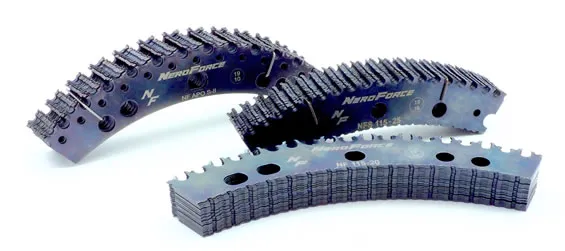

In a complex and innovative manufacturing process, NeroForce produces its own buffing blades for retreading.

NeroForce Relies on Traditional Manufacturing Techniques

The new blades, which are designed to achieve particularly long service life, are manufactured and hardened in a novel process.

According to NeroForce, blades manufactured by the competition are often simply hardened as “bulk goods” on a conveyor belt. NeroForce, on the other hand, first fixes the punched blanks made of high-quality High Carbon Steel individually in a special device before they undergo the hardening process. This special technique enables NeroForce to achieve a much better uniform heat treatment for each individual blade. The result is not only an extremely homogeneous hardening process, but the blades remain absolutely flat and do not show any bending, a common problem with this kind of product. This, says NeroForce, is the only way to ensure optimum tooth position when fitting into the buffing head, as calculated precisely on the drawing board during the technical development.

A further feature of the NeroForce buffing blades is the bluish colouring, caused by the special hardening bath. Retreaders will remember this feature, because in the past all blades were hardened in this manner until it was decided to use cheaper hardening processes. However, NeroForce relies on the traditional technique, which, together with the aforementioned fixing of the blades during hardening, not only makes a significant optical difference, but also provides much longer service life and more effective performance.

“Our buffing blades have convinced many of the most renowned retreading companies within a short period of time, which clearly shows that we are on the right track with our concept – quality and innovation convince!” adds Andreas Müller, one of the managing directors of NeroForce GmbH.