CIMA, a global leader in the manufacture of curing presses for the tyre retreading industry, has announced the launch of its upgraded ECOLINE press range. This latest addition to its product line-up is segmented into three distinct offerings, each designed to enhance energy efficiency significantly within the retreading process.

Innovation For Energy Saving

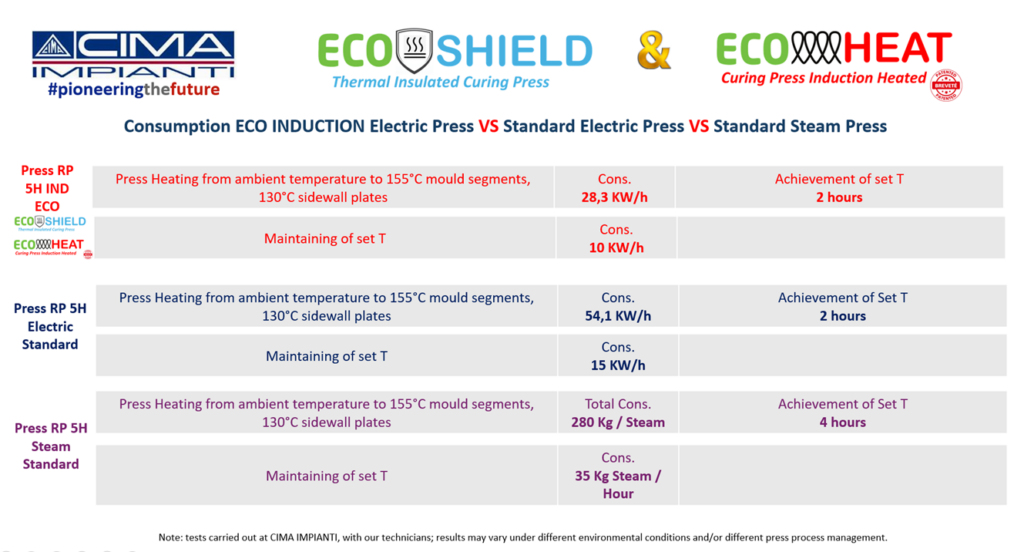

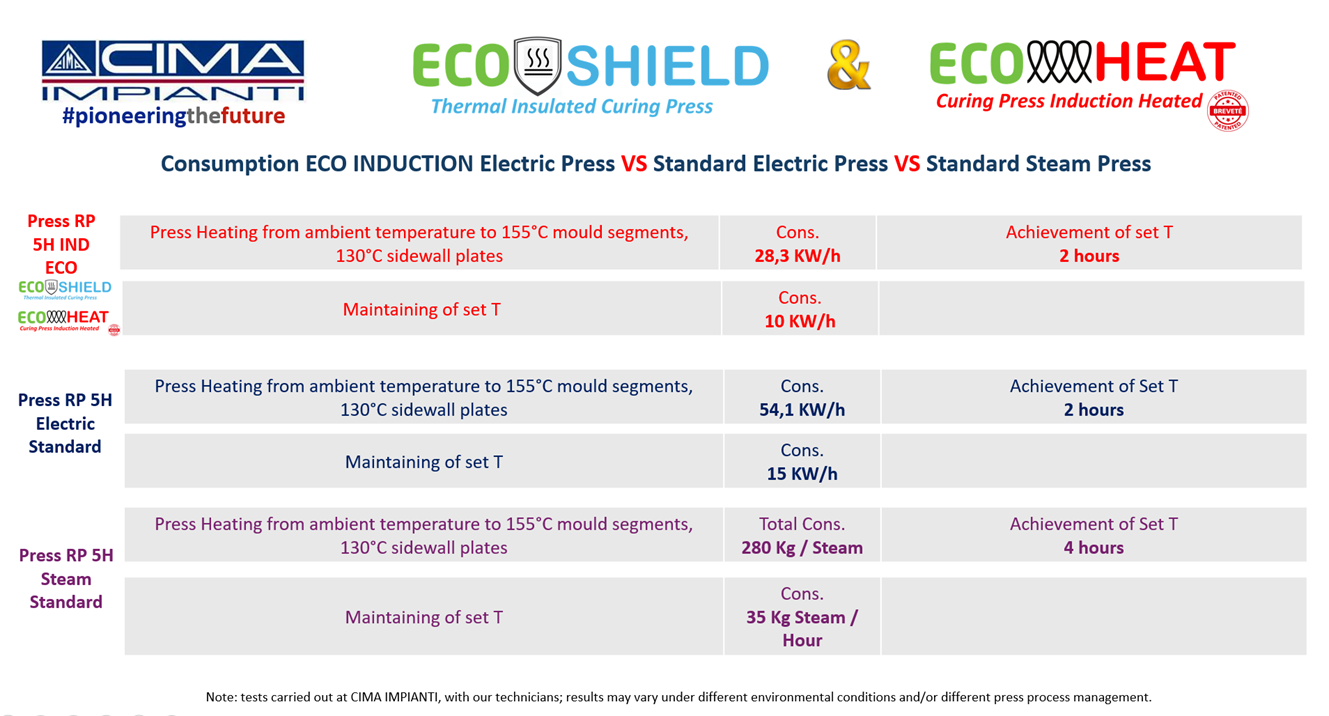

The highlight of the ECOLINE range is its remarkable energy-saving features, which are set to redefine industry standards. Since commencing manufacture in 2010, CIMA has been at the forefront of developing presses that offer customisable cavity features, enabling interchangeability and flexibility. This flexibility extends to compatibility with products from other brands, ensuring retreaders can keep using existing moulds designed for other brands inside this flexible cavity CIMA press. A standout feature of the new ECOLINE press is its insulated cavity, ECOSHIELD, which directs all generated heat towards the tyre, maximising efficiency. The shift from steam to induction heating with part two of the line-up, ECOHEAT, represents a significant advancement, offering the efficacy of an electrically heated press with half the power consumption.

The third part of the new release, HOT N2, is central to further innovation, which introduces a separate nitrogen module tailored to benefit the retread tyre industry and new tyre manufacturing. Due to nitrogen’s inert gas properties, the life of the bladder is considerably extended, and thanks to the fact that nitrogen is heated, the curing cycle time is reduced. Capable of integrating with existing systems and delivering up to 28 bar of pressure and 240 °C of temperature, this separate standing item can be used in the new tyre curing process as well.

These innovations collectively contribute to a substantial energy saving compared to traditional presses. Such efficiency gains benefit all mould cure retreaders, but more so for pre-cure retreaders who want to complete their product range with some mould cure; these can incorporate the ECOLINE range into their operations without the complexities associated with piping and ancillary infrastructure. The move towards more sustainable, emission-reducing technologies underscores CIMA’s commitment to environmental stewardship.