Times are changing. A generation has passed since the heyday of passenger tyre retreading in Europe, when the likes of Technic, at that time the largest passenger retreader in the world, was churning out up to 70,000 retreads per week.

Continental Unveil Conti GreenConcept Tire at IAA Mobility

Those days are long gone, and you could be forgiven for thinking that passenger retreading was forever destined to be labelled as a niche sector, restricted to serving specialist applications in the 4×4 and motorsport markets.

However, there are signs that the new tyre manufacturers, who have long eschewed deliberately manufacturing passenger tyres with an inbuilt capacity for retreading, have begun to take on board the sustainable credentials of passenger retreads, and have started to look seriously at their retreading potential.

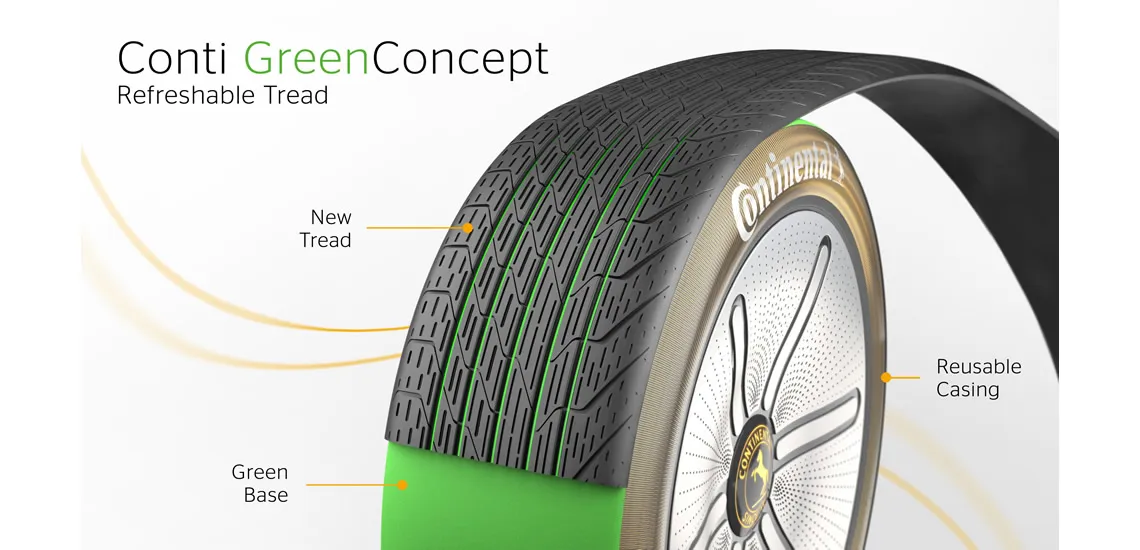

This was demonstrated at the recent IAA Mobility event in Munich where Continental introduced its innovative GreenConcept tyre, a conceptual study which leverages both current and emerging technological approaches to the engineering of sustainable passenger tyres. The goal of the concept was minimising resource consumption across every link in the tyre’s value chain. As such, the study addressed everything from the sourcing and procurement of raw materials on to the various stages of production and even on up to ways of extending the tyre’s service life. The result was a tyre that consists of a particularly high percentage of traceable, renewable, and recycled materials, has an innovative, lightweight design that conserves valuable resources, and an extended service life thanks to a renewable tread.

“Conti GreenConcept underscores our commitment to becoming the most progressive tyre company in terms of environmental and social responsibility by the year 2030, and this ambition applies to every single link in the value chain,” commented David O’Donnell, responsible for Continental’s global tyre original equipment business, adding: “The way we see it today, sustainably sourced raw materials, lightweight design and tread renewal are the key ingredients in making future generations of tyres more sustainable. Our concept study exemplifies Continental’s ongoing efforts to fully transition its global tyre production to sustainable materials.”

A key element of the Conti GreenConcept is the idea that the tread can be renewed with a minimum investment of both time and materials. Depending on the intended use and driving style, Continental says that its calculations indicate that the tread strip, consisting of 100% Taraxagum rubber compound, will wear out after approximately 20,000 kilometres, and can then be retreaded multiple times, with a minimal investment in terms of both time and materials, thereby halving the amount of material used for a casing as seen in terms of its total mileage.

Besides the concept study launched at IAA Mobility, Continental says its R&D team is looking very closely at retreading possibilities for passenger tyres in general, but says it is still too early to talk about concrete plans or timings. A particular focus of the company’s current investigations is how close a retreaded passenger car tyre can get to matching the properties of a new tyre. Two important aspects under scrutiny are rolling resistance and performance under high-speed conditions – mutually conflicting goals in tyre engineering that can pose special challenges in terms of such safety-critical parameters as braking and traction. “For us, as a premium tyre manufacturer, safety is the top priority, and something we will never compromise on, says the company.