KRAIBURG Austria has announced the launch of a new, web-based tyre pressure monitoring system called TYLOGIC, which reliably detects gradual or abrupt pressure loss, possible mechanical damage to axles or brakes of the truck or the imminent end of the regular tyre mileage.

Tylogic is KRAIBURG’s Latest Innovation

It warns drivers and fleet managers immediately when deviations or problems occur and prevents a drop of more than 10% below the recommended tyre inflation pressure from going undiscovered. The new system was developed in cooperation with Czech company, Auris, which has specialised in the development of software and hardware systems for transport companies for more than 25 years.

The new TPMS from KRAIBURG focusses on the transparent and secure handling of tyre data, including information on tyre inflation pressures, mileage and maintenance intervals as well as the statistical evaluation of the actual mileage of tyres according to type. A GSM network collects the data, e.g. on maintenance tracking and tyre breakdowns, at regular intervals, and these are transmitted to a database administrated by the fleet manager. On request all collected data is accessible for analysis purposes.

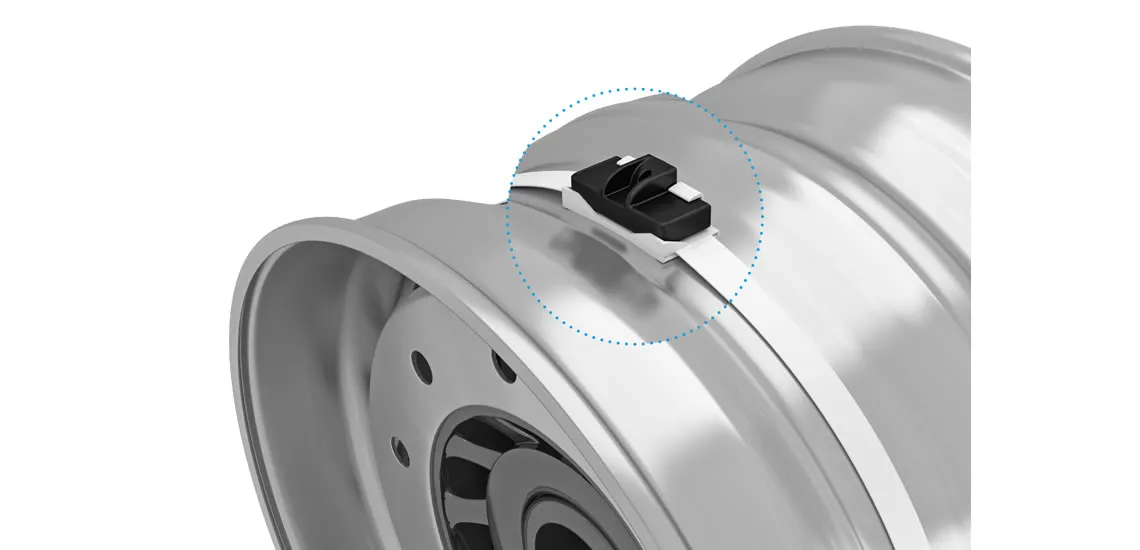

The TYLOGIC TPM system – unlike similar products – is a brand-independent system and is therefore suitable for all tyre types, sizes, positions, uses and vehicle models. It can be used for an unlimited number of tyres and is suitable for light and heavy commercial vehicles. Mounted on the rim, it works equally well for summer and winter treads. The standard version consists of six tyre sensors and a receiver unit. The sensors are mounted on the individual tyre rims. There, they measure the tyre inflation pressure and temperature in every tyre. TYLOGIC detects an inflation pressure deviation in any combination and also whether only one tyre or all six tyres simultaneously are affected. The data is transmitted by radio-frequency signal (RF) to an electronic control unit (ECU). When the tyre pressure drops below a certain inflation pressure limit, the driver immediately receives an alarm. The TPMS displays tyre information in real time – everywhere, whilst travelling and parking. If the tyre inflation pressure or temperature deviate from the nominal values, TYLOGIC automatically alerts a preselected circle of people by SMS or e-mail, who can intervene rapidly and prevent unnecessary costs.

Tyre failure is one of the most frequent causes of breakdowns, generating high vehicle repair and breakdown service costs of an average 1,000 Euro (assuming one tyre failure per unit every five years). Incorrect air pressure also leads to an uneven wear pattern and considerably affects the mileage of the truck tyres. TYLOGIC not only prevents this; it also reliably and individually increases mileage through automatic tyre pressure and temperature monitoring. And it does so with a low investment effort but optimum cost-benefit effect. The right tyre pressure improves the drivers’ safety, on the one hand, and the mileage per gallon of the truck and the resulting emissions, on the other hand. Almost two thirds of all commercial vehicles show a twelve-per cent deviation (approx. 1 bar) from the nominal tyre pressure. The TYLOGIC early-warning system offers users the opportunity to adjust the tyre pressure in good time and therefore reduces the fuel consumption and CO2 emissions by a lower rolling resistance. If the users discover a tyre with a mileage considerably below average, they are able to trace its performance curve, even if the tyre was fitted to several vehicles in different positions. This helps to specifically identify possible causes of improper use – a basis for effective service planning.

The newly developed TYLOGIC TPMS is available as TYLOGIC Basic and as TYLOGIC Power. The Basic version contains one communication unit per truck and trailer with six sensors and assembly systems as well as a three-year web service contract. The Power version additionally has a power supply unit, which works independently of the vehicle electrical system for five days and which is suitable for use on trailers. Both versions reliably provide greater economy and safety because they both put drivers and fleet managers fully in the picture.